Supercharge!

0 to100 m.p.h. in 14 seconds in a HR Holden

by Eldred Norman

Chapter 7 - The Carburetor - The Fuel Supply

The carburetor on the average family car is generally far too small for anything but a very mediocre performance. For the sake of good fuel economy, manufacturers particulary of American cars, tend to keep maximum choke velocities as high as 450 feet per second. This permits them to use mixtures rather on the lean side since at these velocities atomization is very effective. But of course performance must suffer, particulary at high speeds.

Racing cars use choke velocities as low as 125 f.p.s. when on full throttle but of course the driving conditions are very different.

Unfortunately most carburetors with fixed chokes, representing by far the greatest number, all have a tendency to develop flat spots at low revs if choke velocities are not kept fairly high.

To partially overcome this disability manufacturers have recently started to turn to the dual throat carburetor with what is know as the progressive link system.

With this type the first three quarters of the throttle movement only operates on one of the two butterflies controlling the passage of air/fuel. The second of the butterflies is actuated by the final portion of the throttle so that it opens very quickly. This system permits reasonably high choke velocities at low speeds provided only the first three quarters of the throttle is used. The whole throttle can be used when the revs. have picked up a bit. This system permits choke velocities of around 250 f.p.s. to function for normal driving.

Unfortunately here in Australia there is a very small range of these carburetors to choose from, and there are none large enough to suit a supercharged car of more than 1500 cc. There are four-barrel versions of this type available in Stromberg, Rochester and Carter, but for a two or two and a half litre car these are rather large. Also the carburetor itself is a fair size. Quite good city driving economy can be obtained by blanking off one of the primaries and leaving the two secondaries available for more throttle on the open road. If too large a carburetor of this type, such as the AFB Carter is used there will almost certainly be a flat spot when changing over to the secondaries.

The horizontal Weber so popular for racing these days is not really suitable for this type of work since it does not use the progressive system.

The unsuitability of many carburetors for a 'blown' car really stems from the fact that there is a far wider range of manifold absolute pressure in the supercharged car. With the atmospheric motor pressures can range from about 2 p.s.i. absolute (-12 on a gauge ) to 14 p.s.i ( almost zero on the gauge ). The blown car will have the same low reading when idling but may well rise to 25 p.s.i. on full throttle. This of course means that the carburetor will have to cope with an 80 % greater range than it was designed for.

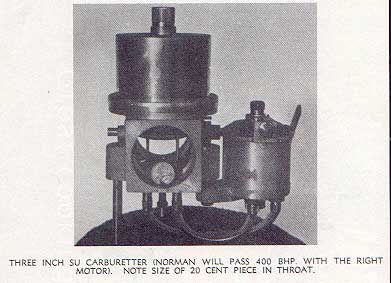

By far the most suitable carburetor all round is the S.U. For racing purposes it is possible to get slightly more maximum power with a Weber than the S.U., but in responsiveness at low and intermediate level there is no comparison, the latter is much superior. For street driving, with its constant choke velocity it has no peer. Unlike the fixed choke carburetor the S.U. can never be too large to upset performance low down.

The matter of carburetor size can play an important part not only in the matter of peak performance, but also in the matter of overall performance. I mentioned in a previous chapter that the axial and centrifugal types tend to outrun an engines breathing inefficiency so that compression pressures are too low at low speeds and too high at high speeds. Of course it is possible to vary this by fitting too small a carburetor and driving the supercharger faster, but of course this wastes power driving the supercharger. The Roots and vane types because of their positive action do not suffer in this way. If anything they have a slight tendency in the other direction because as I also said earlier, an increase in boost pressure is not followed by a proportionate increase in filling and compression pressures.

For this reason both these types of superchargers must use the largest carburetor they can adequately handle taking all the driving circumstances into count. For best all round performance the supercharger should not be 'over-driven' and maximum boost limited by a small carburetor. This will cause pinking and perhaps detonation low down and poor filling up top.

The S.U. can cope best with all these conditions. As a guide only to those intending to supercharge a street car for use with pump petrol. A 1500 would require a single 1 3/4" S.U. A 2 litre a 2" S.U., and a 3 litre two 1 3/4" S.U.s For racing or 'dragging' with higher boost pressures it would be necessary to double up on these.

The S.U. is particularly suited to the use of methanol based fuels since there is only one needle and jet to alter. However, if 'straight' methanol is to be used each carburetor should be fitted with twin float chambers as it will be impossible to pass sufficient fuel through one needle and seat to feed the required jet size. Special 'fuel' S.U.s. are made with the very large float chamber but these are rather hard to come by.

Only those who have had practical experience seem to be able to appreciate the enormous quantity of methanol required for a highly supercharged engine.

Some three years ago I supercharged a 1500 Cosworth Cortina motor with a pressure of 43 lbs. absolute. I used two 2" S.U.s. each fitted with three float chambers, and fed from two half inch lines at six pounds steady pressure, and it was necessary. On full throttle it used fuel at the rate of three gallons per minute. And this was a 1500.

In working with methanol it is a good idea to try and imagine the worst possible fuel consumption you could possibly get on petrol with an engine, then times it by four to be on the safe side. Imagine a three litre car towing a caravan against a strong head wind, 'dead flat' in second gear. In these conditions it would be lucky to get six miles per gallon. On methanol it would require fuel at the rate of two miles per gallon. At 50 m.p.h. it does a mile in 72 seconds, so it would use a gallon of fuel in less than two and a half minutes. Needless to say its own fuel pump would be quite unable to cope with this, and it would starve and melt pistons.

A standard S.U. electric petrol pump would be hard put to it to pass six gallons per hour through one needle and seat. Try it with a measure some time and you will get a surprise.

Probably the most suitable system for supplying fuel to the carburetor in large quantities is known as the 'weir' system. A small gear or aircraft type vane pump is driven from the end of the crankshaft at a suitable speed, usually by a belt. This pump should be mounted low down so that it is self-priming.

Both outlet and inlet must be fitted with tee pieces. One of the branches of the outlet tee is connected to somewhere near the top of the main fuel tank and a similar connection is made from the other tee to the bottom of the fuel tank. Now in place of the usual float chamber on the carburetor we have a small reservoir. The float chamber will do if the float is removed. This must be fitted with two connections, one at float level. The other can be the same level or even above it slightly. The one at a definite float level should be larger than the other; this is the outlet. When I refer to float level I am referring to what was originally float level; there is of course no float in it now. This outlet is connected to the branch of the tee on the inlet side of the pump, and the other connection on the small reservoir is made to the branch of the tee on the pressure side of the pump. This last connection should be restricted near the pump so that the overflow at float level can more than cope with the incoming supply of fuel.

It will be necessary to arrange some form of baffle so that the incoming supply does not cause undue agitation in the small reservoir which might permit the main jet assembly to suck air. The functioning of this system is simplicity itself. The pump circulates fuel all the time to both tank and the reservoir. If the fuel level through consumption falls below the outlet, the pump will suck air but because of its relatively enormous throughput most of this air will be transferred to the fuel tank and fuel and a small quantity of air will be pumped back into the small reservoir. In effect the pump pumps a mixture of fuel and air all the time but of course in both tank and reservoir the fuel settles out.

Provided reasonable size pipes are used this system will cope with the thirstiest of engines as quite a small gear pump will handle ten gallons a minute.

People often ask me if fuel injection would be an advantage with a supercharger. Briefly, the answer is no. The purpose of fuel injection is to offer the least possible resistance to cylinder filling and at the same time introduce a cool and well atomized mixture. No carburetor is capable of doing this simply because of the method of atomization involved. In the case of the supercharged engine, the situation is entirely different. The amount which we can get into the cylinder is not limited by the very small restriction imposed by the right type of carburetor on the induction side of the supercharger, it is limited by the fuel and how much the engine will stand before it disintegrates. A supercharger fitted with fuel injection would without a doubt give a fraction higher boost than with a carburetor. But this means nothing; you can get more boost simply by driving the supercharger a fraction faster.

Now a warning must be given here to those about to supercharge. The standard petrol pump on almost every make of vehicle will be likely to prove inadequate in supplying petrol at high speed. A low pressure gauge tapped into the line from the pump to the carburetor shows a drop in fuel pressure from 3 p.s.i. to less than 0.5 p.s.i. at 100 m.p.h. full throttle, on every Holden I have ever tested. This was so for all Holdens whether supercharged or not and irrespective of model. It was also true of every other car I have tested. It is probable that the actuating lever of the pump gets cam bounce and diaphragm reciprocation almost ceases.

They only real solution to this is to pressurize the fuel tank itself from the pressure manifold of the supercharger. But remembering car petrol tanks are not very strong and a relief valve must be fitted to the tank to make sure that the pressure does not exceed 3 p.s.i. Also a non-return valve must be put in the line from the s/c otherwise the tank will collapse with vacuum when idling. It is also wise to fit another relief valve on the tank which permits air to enter the tank from the atmosphere. This will provide against long periods of driving with no positive pressure in the manifold. In this case the petrol pump will function in the normal way. The pressurized tank will not affect the pump's normal operation as it acts simply like a supercharger.

This is a special Technical Info article, reprinted from the original (and rare!) book that was supplied with superchargers purchased from Eldred Norman, Aussie racing legend and manufacturer of Norman Superchargers.

Although not a common method of modifying an FE or FC, the theory and information about fuel induction, carburettion and so on is fascinating. Many thanks to Tony (IhadaV8) for obtaining the book and providing it to us. Tony in turn thanks Mike Norman, for supplying a copy of his father's book.

Important Note: This document is intended as a guide for those persons interested in repairing or modifying their vehicle. The FE-FC Holden Car Clubs of Australia take no responsibility and accept no liability for the information contained herein. You must ensure that all work carried out and/or modifications made to your vehicle are legal in your state, and we recommend you contact an engineer or your local Traffic Authority for further information.

If you have a technical question about repairs or maintenance on your FE or FC, please post a question on our Discussion Forum.

Home || NSW || Queensland || SA || Victoria || Sign the Book || Chat about FE/FCs || Nationals || Tech Data